Additive manufacturing

FIRST VELO3D SAPPHIRE XC PRINTER IN EUROPE

IN OUR 3D COMPETENCE CENTER

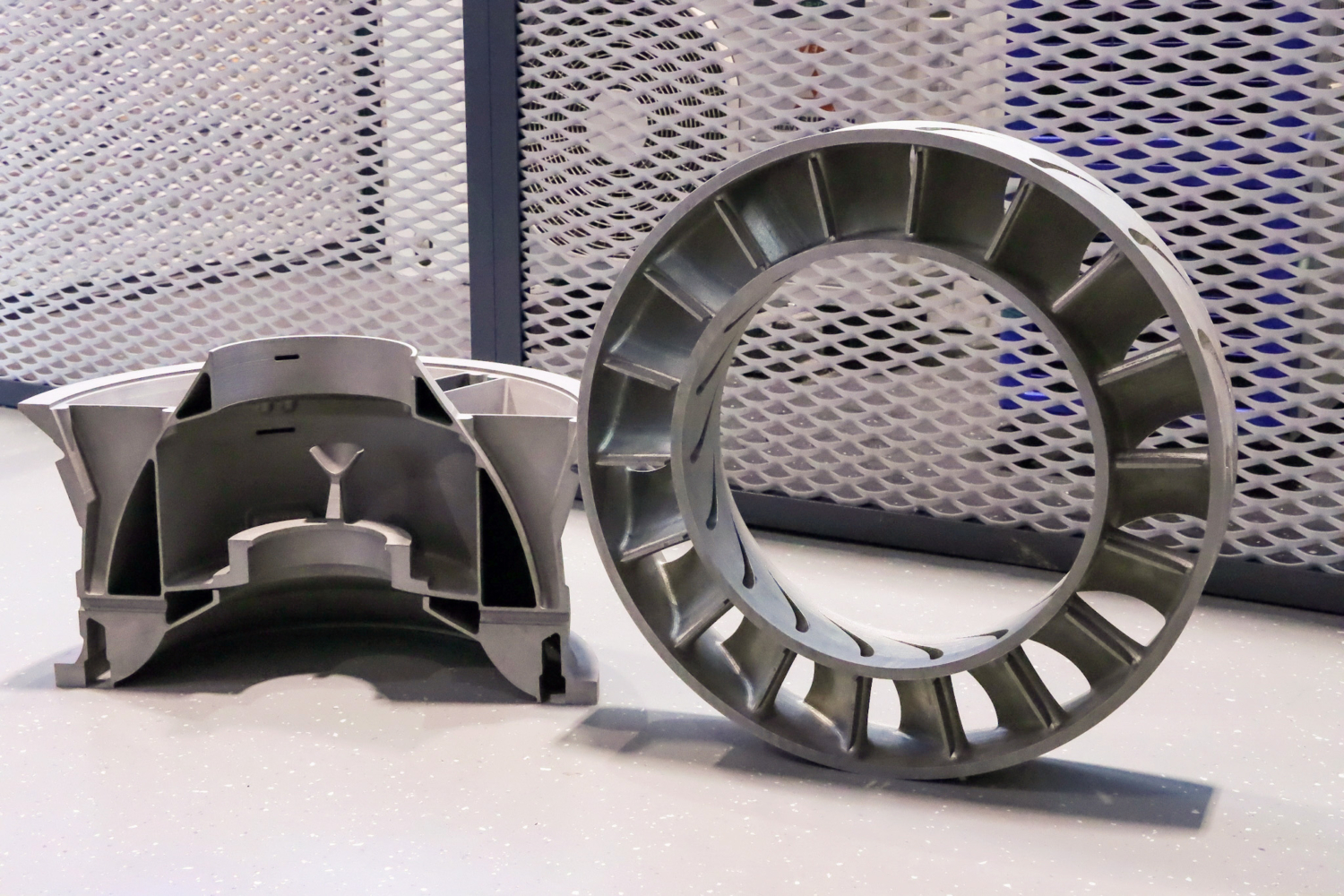

Print sizes up to 600 mm in diameter and 550 mm in height

From concept to complex components in our one-stop production workshop.

You bring the idea, we’ll deliver the finished solution!

Mehr Informationen zum Prototyping finden Sie hier.

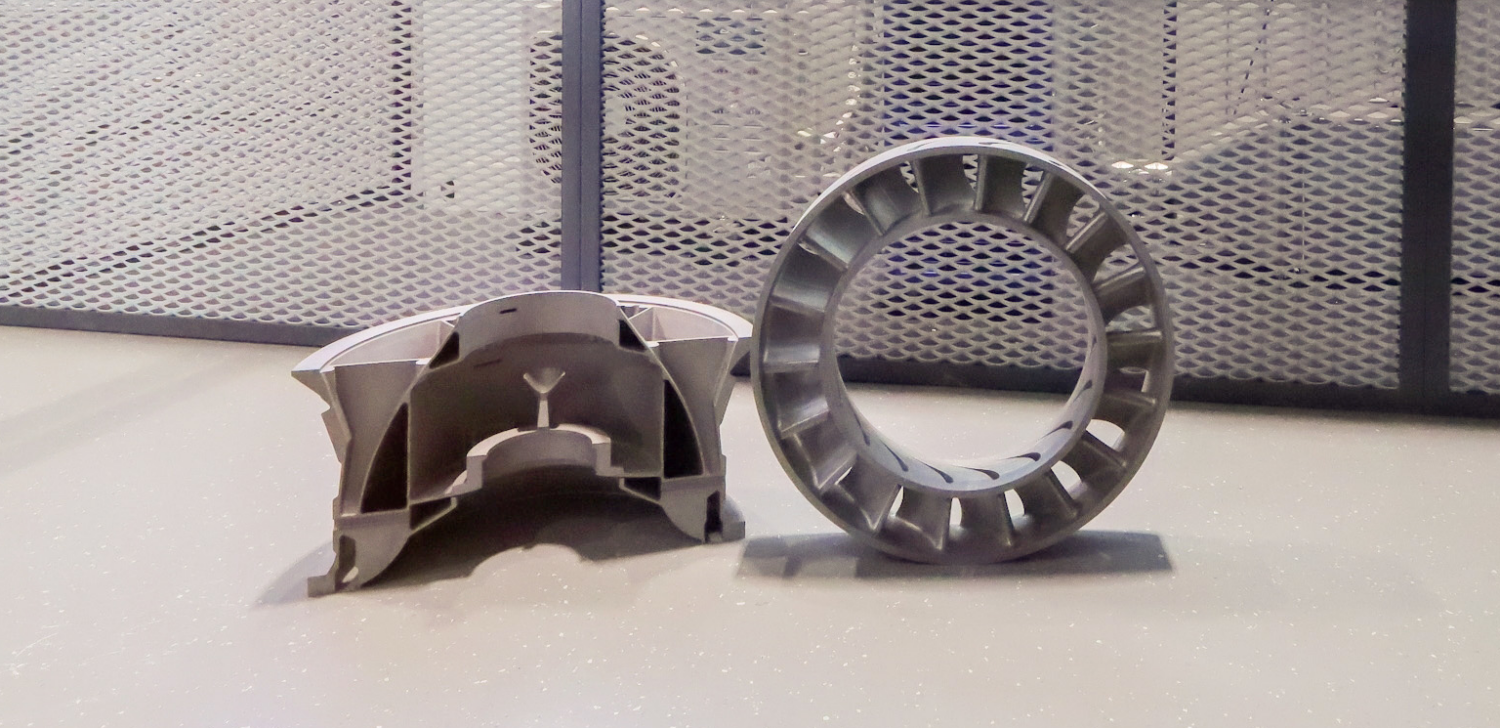

Limitless possibilities in the manufacture and design of metal components

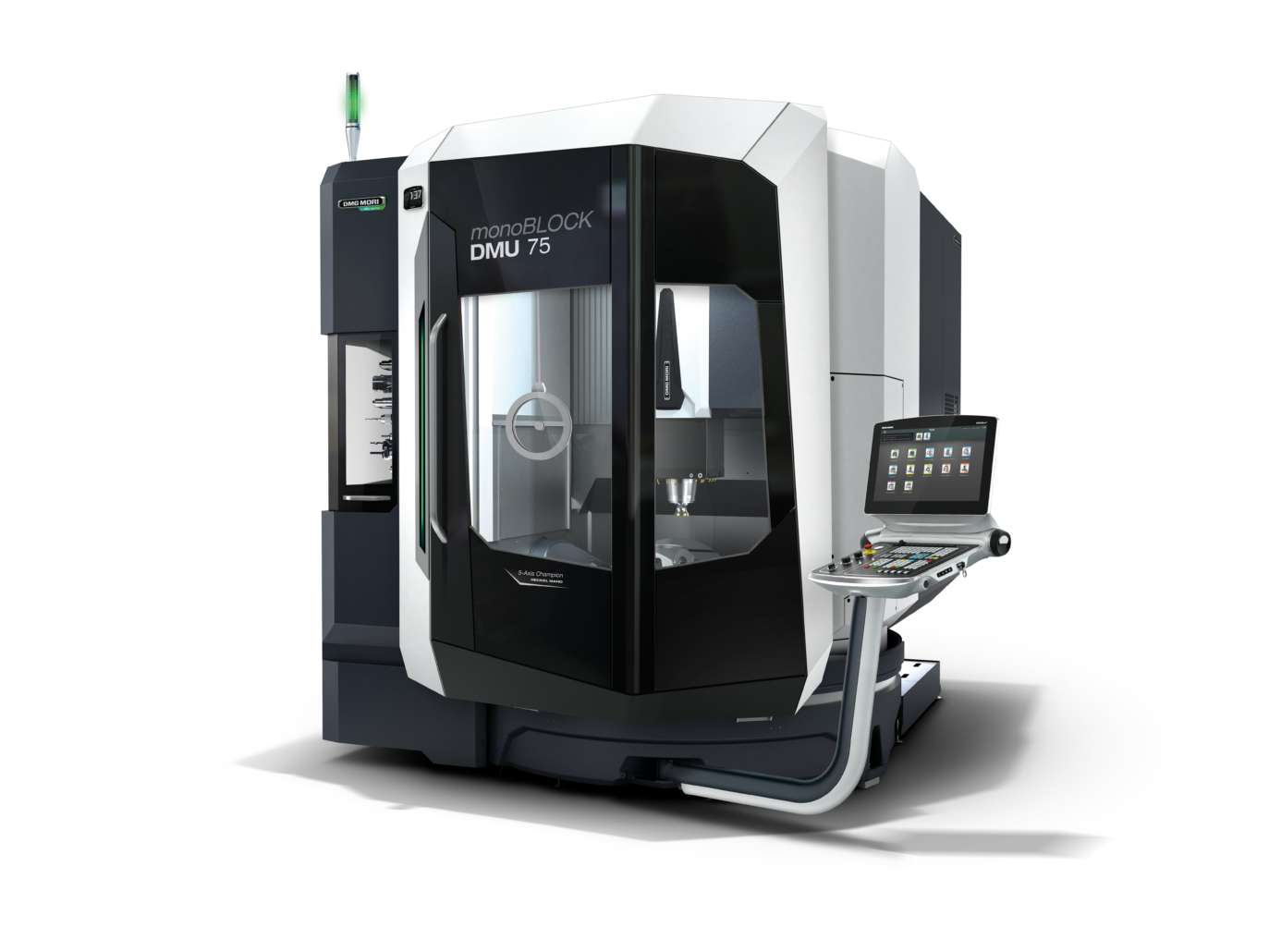

We are a leading manufacturing company with unique technologies and decades of experience in the production of mission-critical components. As the first company in Europe with a Sapphire XC 3D printer in its machine park, we are very proud to be able to offer remarkable capabilities for numerous business areas. We also offer material testing and machining options such as CNC turning, milling and heat and surface treatments for the precise post-processing of 3D components, which we can therefore deliver ready for use—we are your one-stop store! Benefit from our experience in the manufacture of high-tech components for the demanding oil and gas industry, our original main area of business.

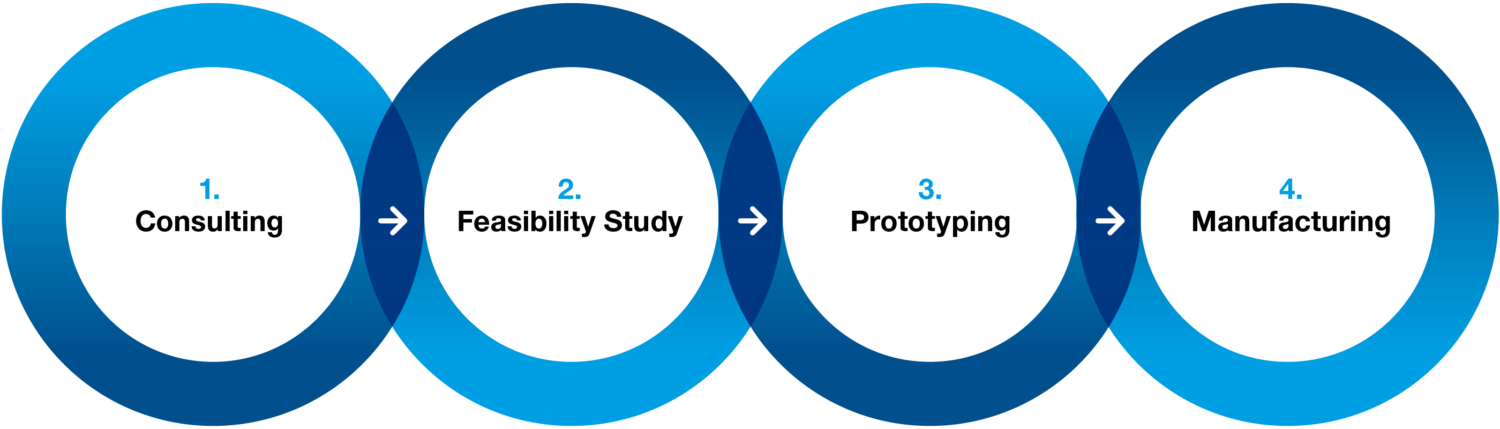

In our competence centre for additive manufacturing, we support your 3D printing project from consultation to feasibility studies, prototyping and series production. Our 3D printers are designed to print large metal components up to 600 mm in diameter and 550 mm in height.