About us

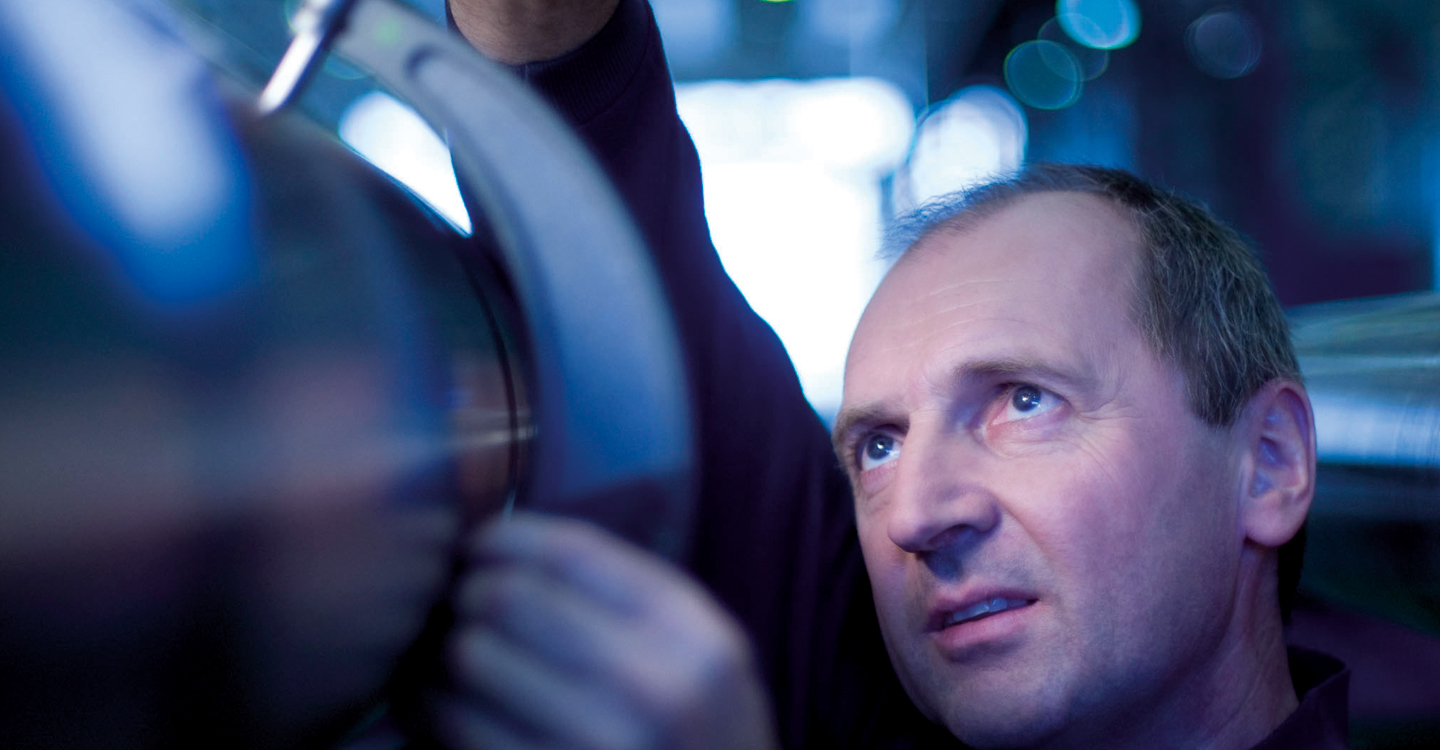

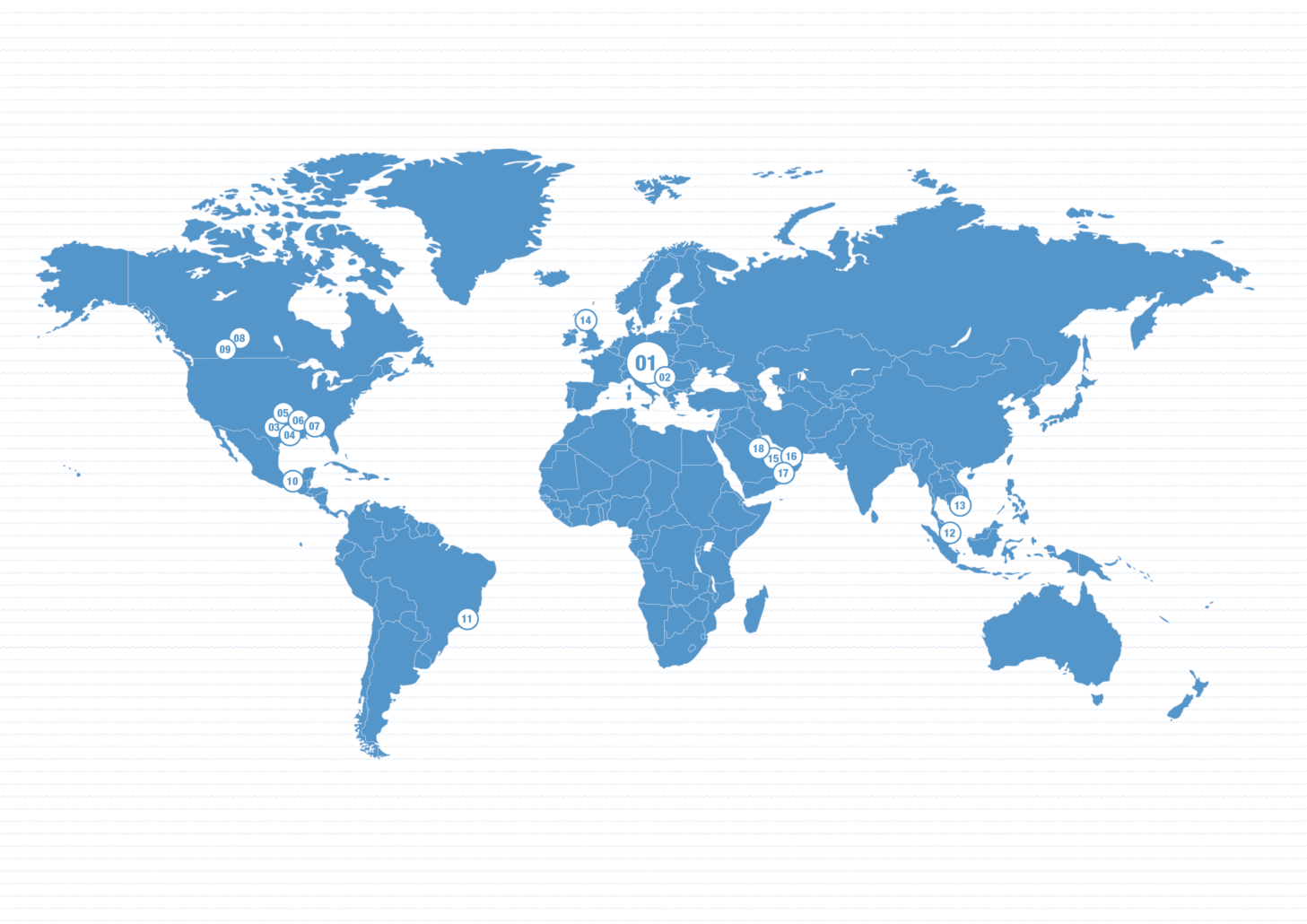

Schoeller-Bleckmann Aerospace Technology (SBAT) a Schoeller-Bleckmann Oilfield Equipment (SBOE) brand operates out of 18 global subsidiaries.

We serve aerospace and aviation customers across our supply chain networks, predominantly in Europe, the US and Asia. Our strategic focus has lead us into the aerospace market and aircraft industry, which have been identified as adjacent markets with synergistic attributes for business growth.

Metallurgical expertise and innovative engineering are at the heart of our DNA. We provide special alloys together with high precision, hard metal complex machining capabilities.

Additionally, we have built our reputation and extensive track record on special processes, additive manufacturing technologies and composite integration with metallic components.

Our service offering

Through more than a century of experience we have constantly developed leading edge technologies and

built our core capabilities around high precision machining.

11 Countries

18 Operating Sites

Annual Sales

€ 291 Meu

1130 Employees

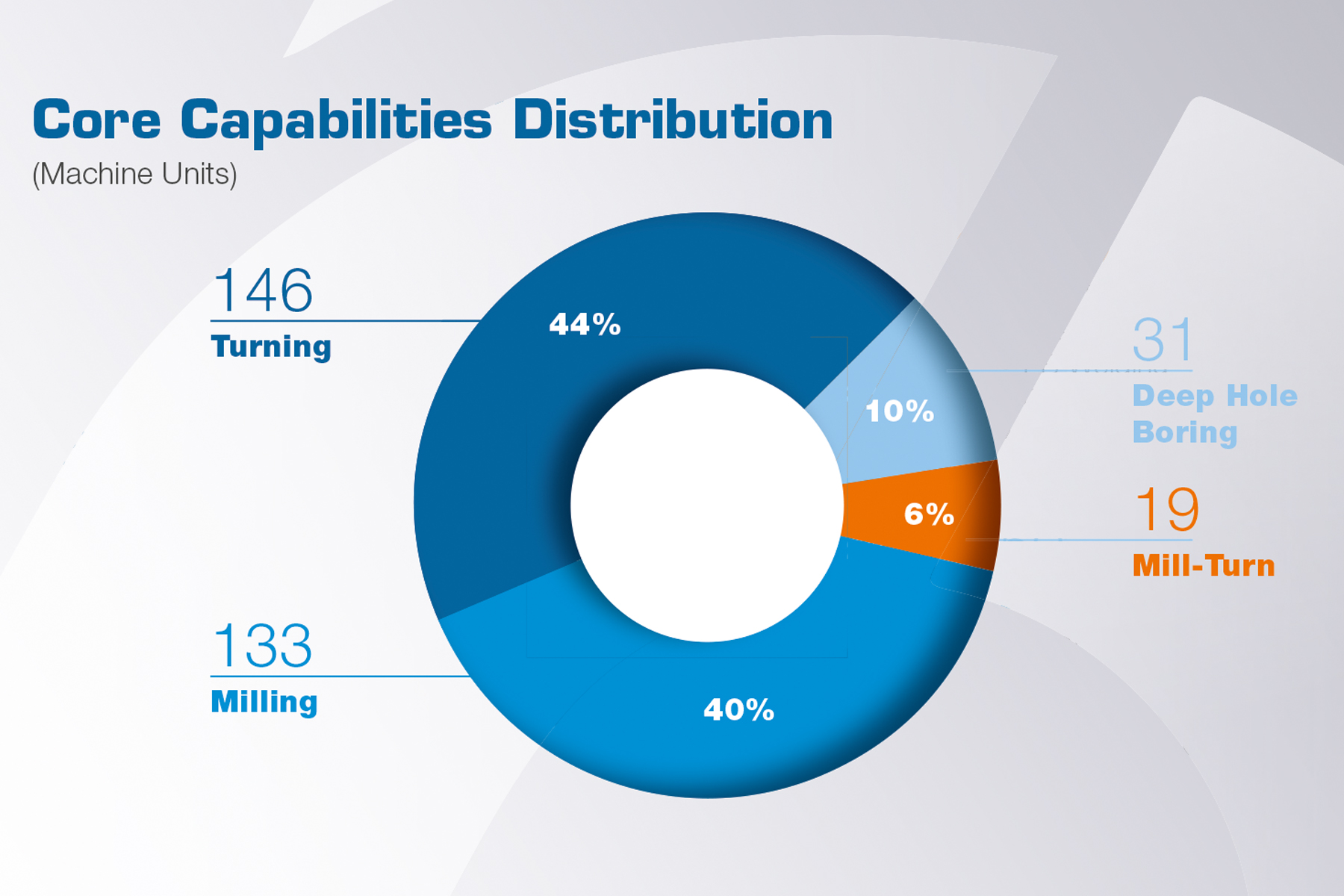

450 + CNC

Machines

Material engineering & provider

Our metallurgical knowledge enables us to provide our customers with raw material solutions to meet specific requirements such as high strength and extreme conditions resistance.

>>more

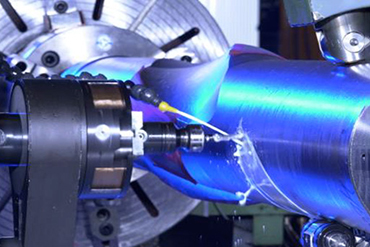

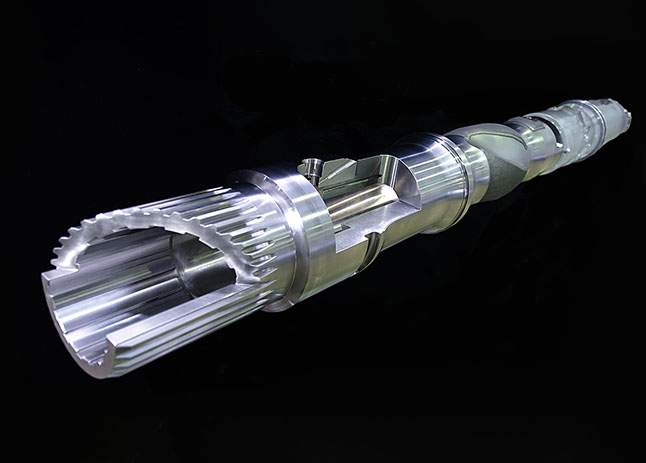

High precision machining manufacturer

Metal processing with the highest precision – from the drawing to the high-end product – our service according to your requirements. You benefit from our modern CNC machines and CAD / CAM solutions, which enable us to manufacture high quality products at fair prices.

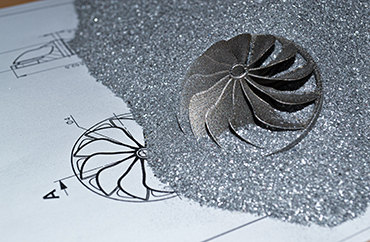

Manufacturer of innovative prototypes

We are able to convert the CAD data you have provided into a workpiece in the shortest possible time using rapid prototyping. Depending on the complexity of the task, we can produce a “first article” in 8 to 10 weeks.

Precision is our calling card. We check your newly designed, complex component for technical suitability and acceptance in coordination of material and production technology.

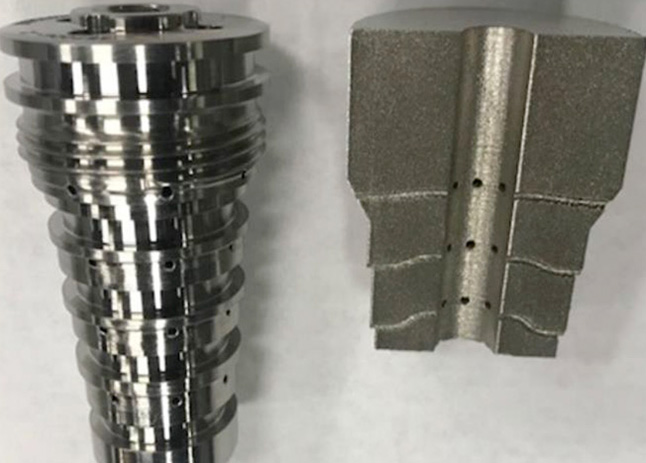

Additive manufacturer

With 3D printing, complex components can be created in a short time as a cost-effective alternative to conventional processes. Schoeller-Bleckmann Oilfield Technology draws on 10 years of group-wide experience with 3D metal printing and supports its customers in 3D prototyping as well as in the implementation, planning and design of their projects with additive manufacturing.

Goose Neck Drilling

Gunhole Drilling

On our special Gundrilling machines we can drill centric and eccentric holes from a diameter of 0,08 in. Drilling depths with a maximum L/D of 500 are possible. Our patented directional drilling system guarantees minimal drilling. This deep drilling method also allows us to create machining operations with a specific course.

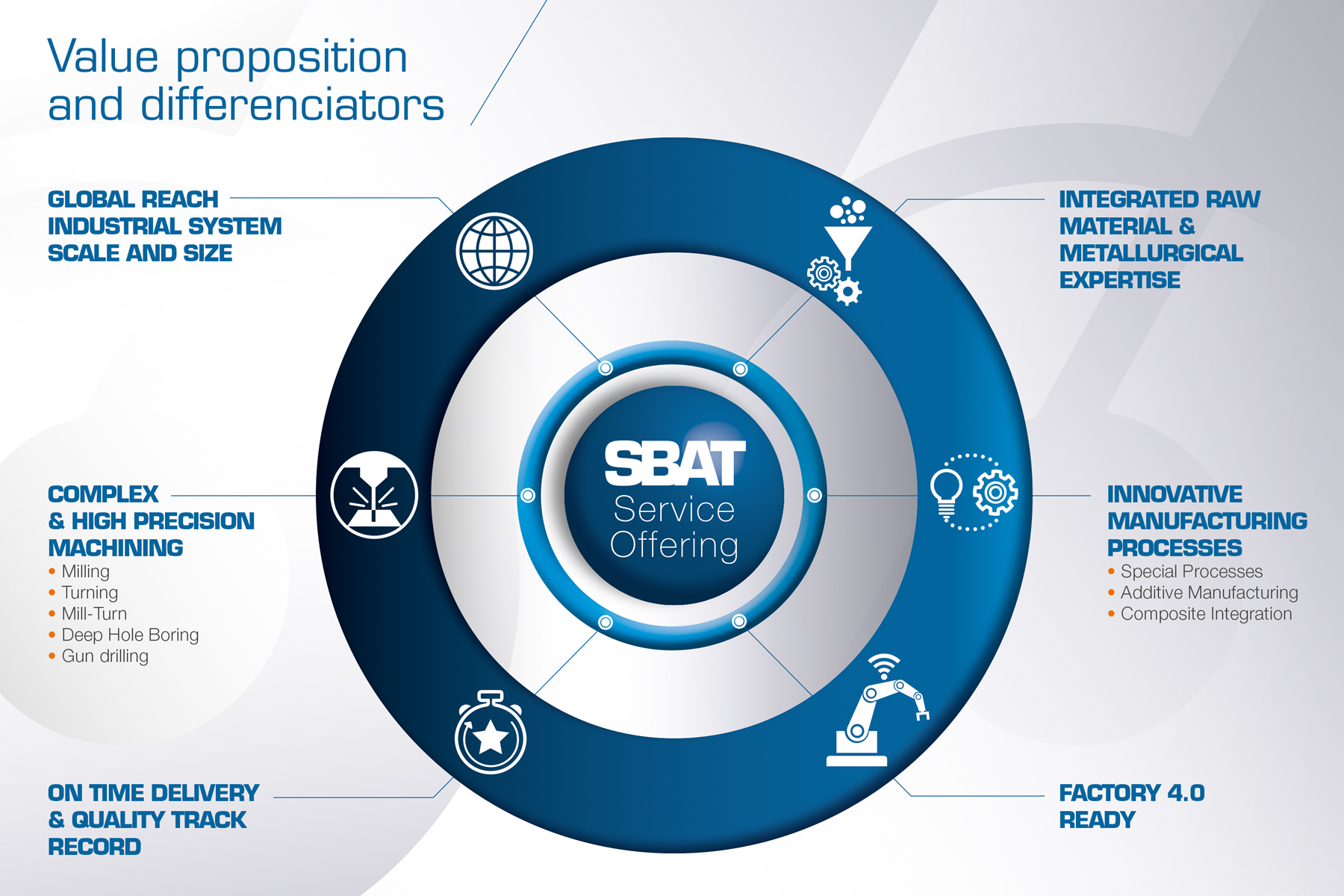

VALUE PROPOSITION

Our service offering is what makes us

different and what defines our expertise.

The excellent product quality is a trademark of our company.

A strict control system guarantees an excellent end product.

The entire value creation process is part of our quality management system, which has been certified several times, and extends from the procurement of raw materials through precision machining to the final inspection of the finished products.

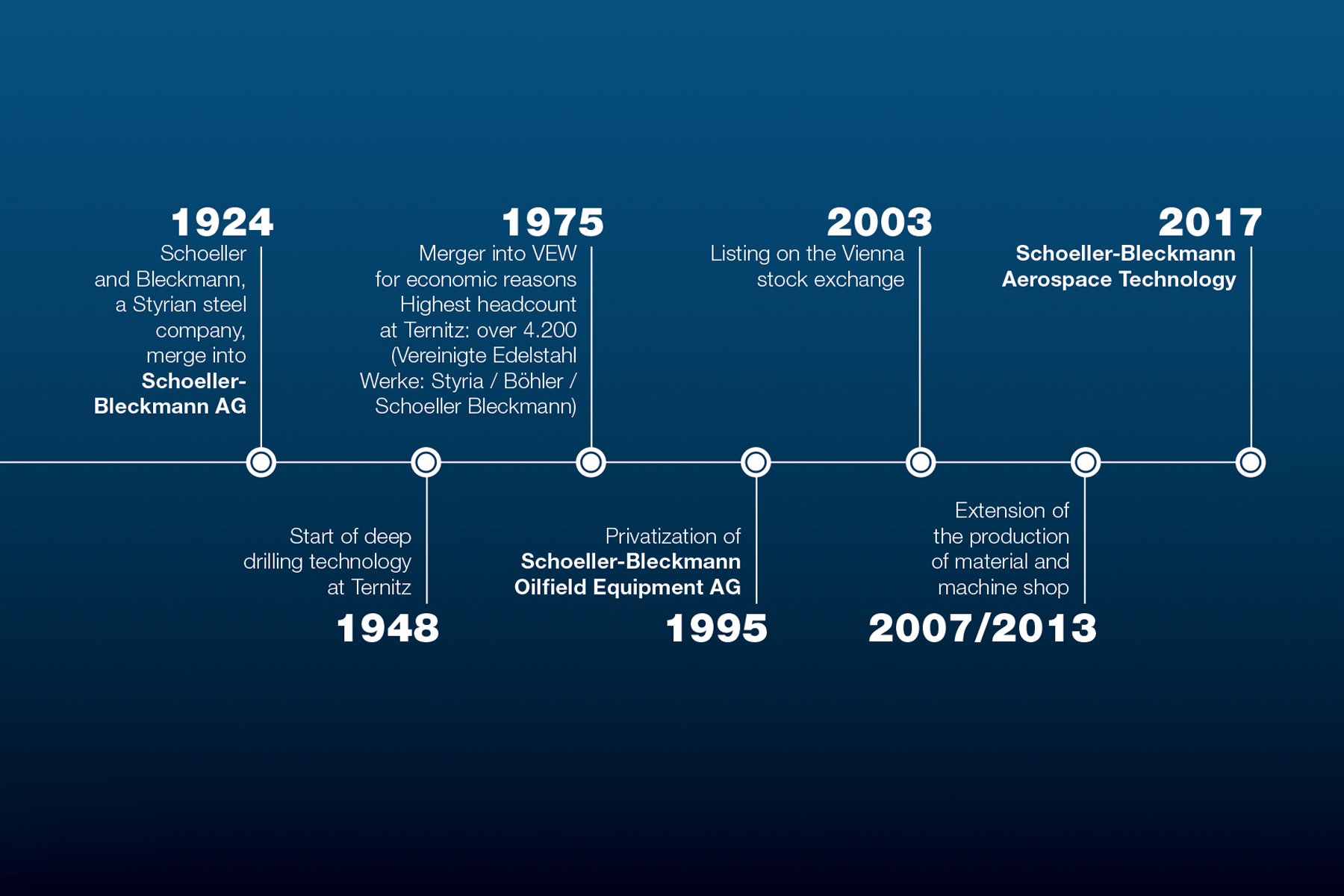

Our history defines who we are. Since 1924, Schoeller Bleckmann has grown and developed its expertise all over the years. Perfecting its skills in the oilfield equipment, the group is writing a new page of its history with the creation of the Schoeller Bleckmann Aerospace Technology brand.

Global manufacturing landscape

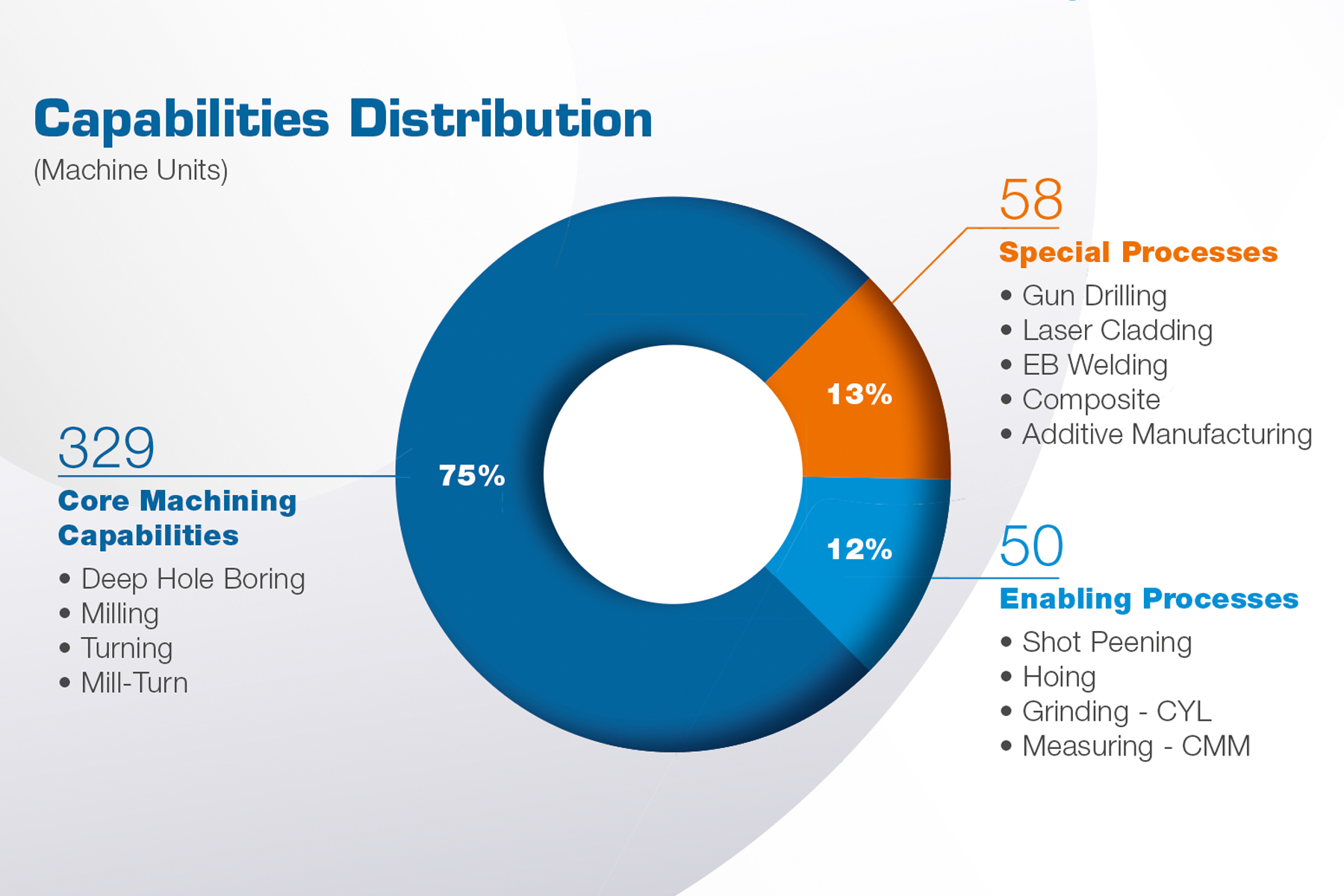

Capabilities Distribution

Core capabilities Distribution

| Manufacturing Process | Ø | ↔ | X | Y | Z | Information |

|---|---|---|---|---|---|---|

| [mm] | [mm] | [mm] | [mm] | [mm] | ||

| Turning | 25 - 70 | 13.000 | N/A | N/A | N/A | 2 & 3 axes |

| Milling | N/A | N/A | 6.000 | 1.200 | 3.600 | 3 & 5 axes |

| Gundrilling | 3 - 25 | 4.500 | N/A | N/A | N/A | 1 & 2 axes |

| BTA Deep Drilling | < 250 | 13.000 | N/A | N/A | N/A | 1 & 2 axes |

| Turning-Milling | < 600 | 12.000 | 6.000 | 800 | 2.500 | 5 axes |

Part of Schoeller-Bleckmann Oilfield Equipment (SBOE), we operate all over the world. We have three different types of sites: our headquarters, our high precision component manufacturing site and our maintenance & regular services sites.

Our case studies

Discover some of our work that shows the extent of our expertise.