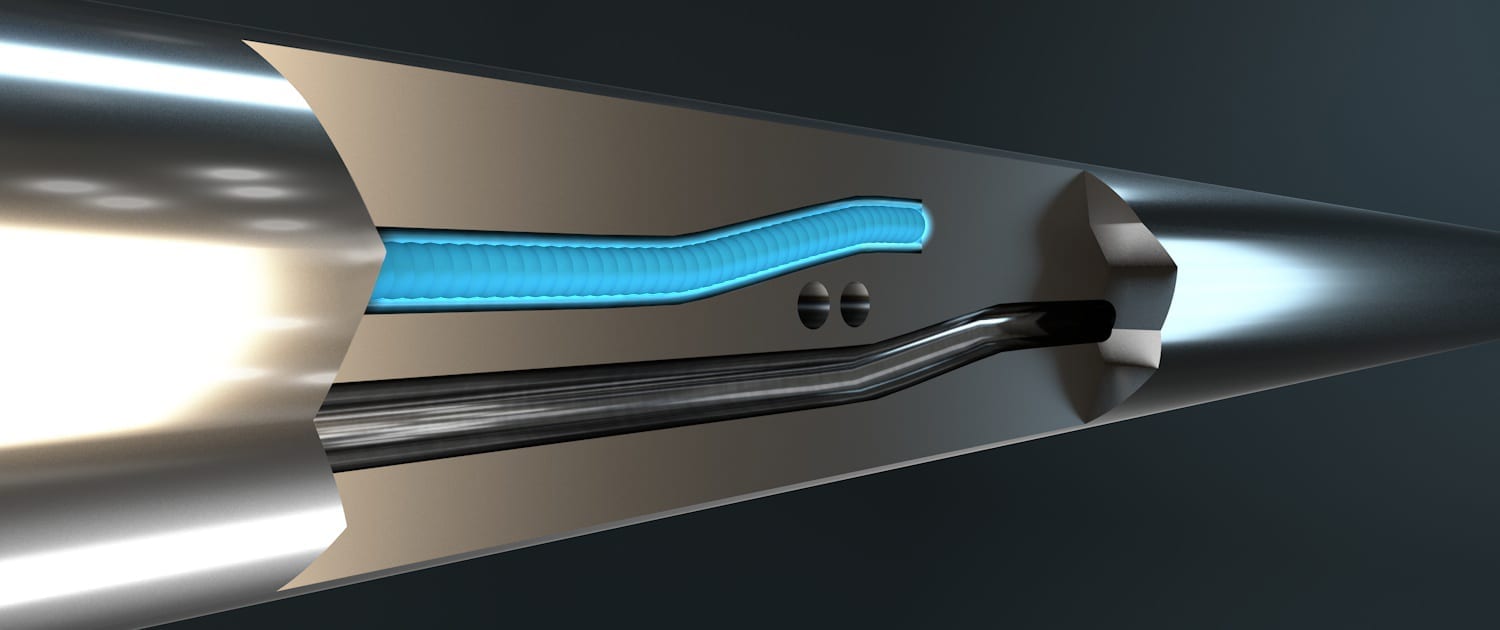

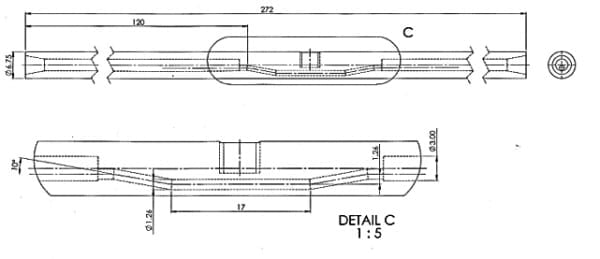

The erosion process – Goose Neck Drilling – short GND – developed together with the TU Vienna makes it possible to drill curved bores into workpieces.

After five years of development, Schoeller-Bleckmann Oilfield Technology applied for a patent in 2015.

GND allows the creation of deflected bores with controlled flow inside a metallic workpiece by using EDM processes.

Benefits

Application Examples

EDM with sparks is used where mechanical machining of difficult-to-machine materials reaches its limits or where mechanical machining is not possible due to geometric requirements.

Materials

- high-strength steels

- high-alloy metals

Goose Neck Drilling – The Process

Electrical discharge machining (EDM) is a thermal manufacturing material-removing process for conductive materials based on electrical discharge between an electrode and a conductive workpiece.

The complete machining of the workpiece takes place in a non-conductive liquid, which is usually deionised water or oil.