We manufacture made to measure for you!

Our capabilities support your engineering design through to finish component.

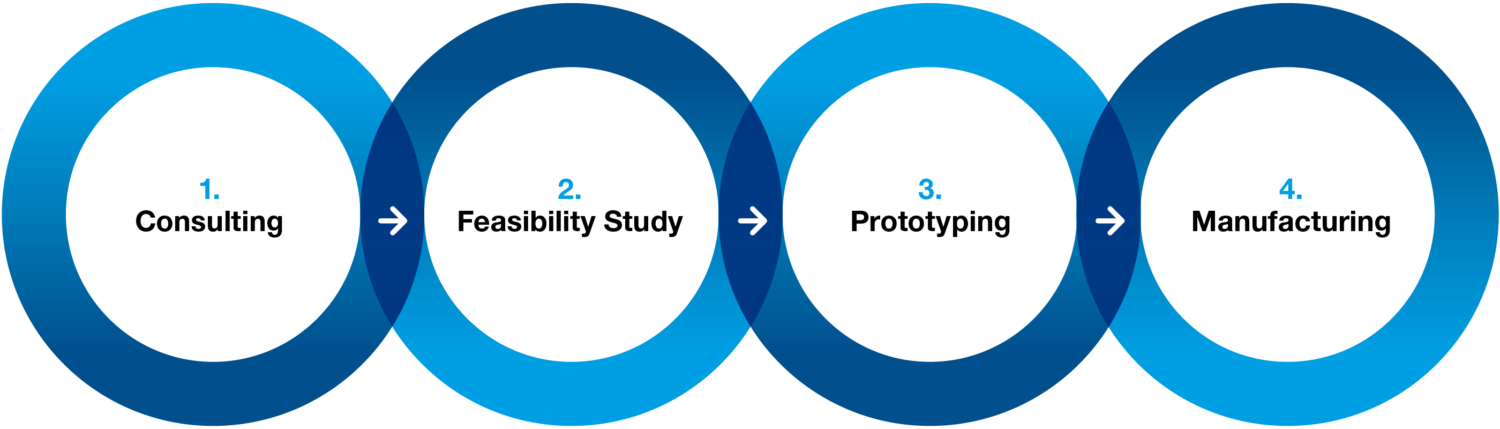

On the basis of our high precision engeneering competence, we offer our customers the following services during initial production.

Rapid Prototyping

We are able to convert the CAD data you provide into a workpiece in the shortest possible time using rapid prototyping.

Depending on the complexity of the task, we can produce a “First Article” in 8 to 10 weeks.

Precision is our calling card.

We test your newly-designed, complex component for its technical feasibility and acceptance in coordination with material and production technology.

We work on the basis of the latest scientific findings. This enables us to offer our customers the widest possible technical spectrum for the most varied range of applications.

from technical drawing > to 3D model > to prototyp

One stop shop for fast prototyping!

Comprehensive know-how coupled with great expertise in a wide range of production types makes us a partner at eye level with vision.

Efficient prototyping is a decisive step in product development, paving the way from the feasibility study to the production of individual parts and small series. Through the targeted use of modern prototyping technologies, companies can optimize their time and resources. The feasibility study enables a precise evaluation of design ideas before expensive production processes are initiated. Prototypes serve as tangible models to test design concepts and identify potential challenges at an early stage.

Advanced manufacturing technologies, such as 3D printing, offer flexible and cost-efficient solutions for the production of prototypes and series. The iterative nature of the prototyping process allows for quick adjustments and optimisations, which ultimately increase the quality of the final product. The seamless transition from feasibility study to prototypes and finally to production enables our customers to bring innovative products to market faster and secure competitive advantages. Overall, efficient prototyping promotes innovation and agility in product development.