Schoeller-Bleckmann Oilfield Technology

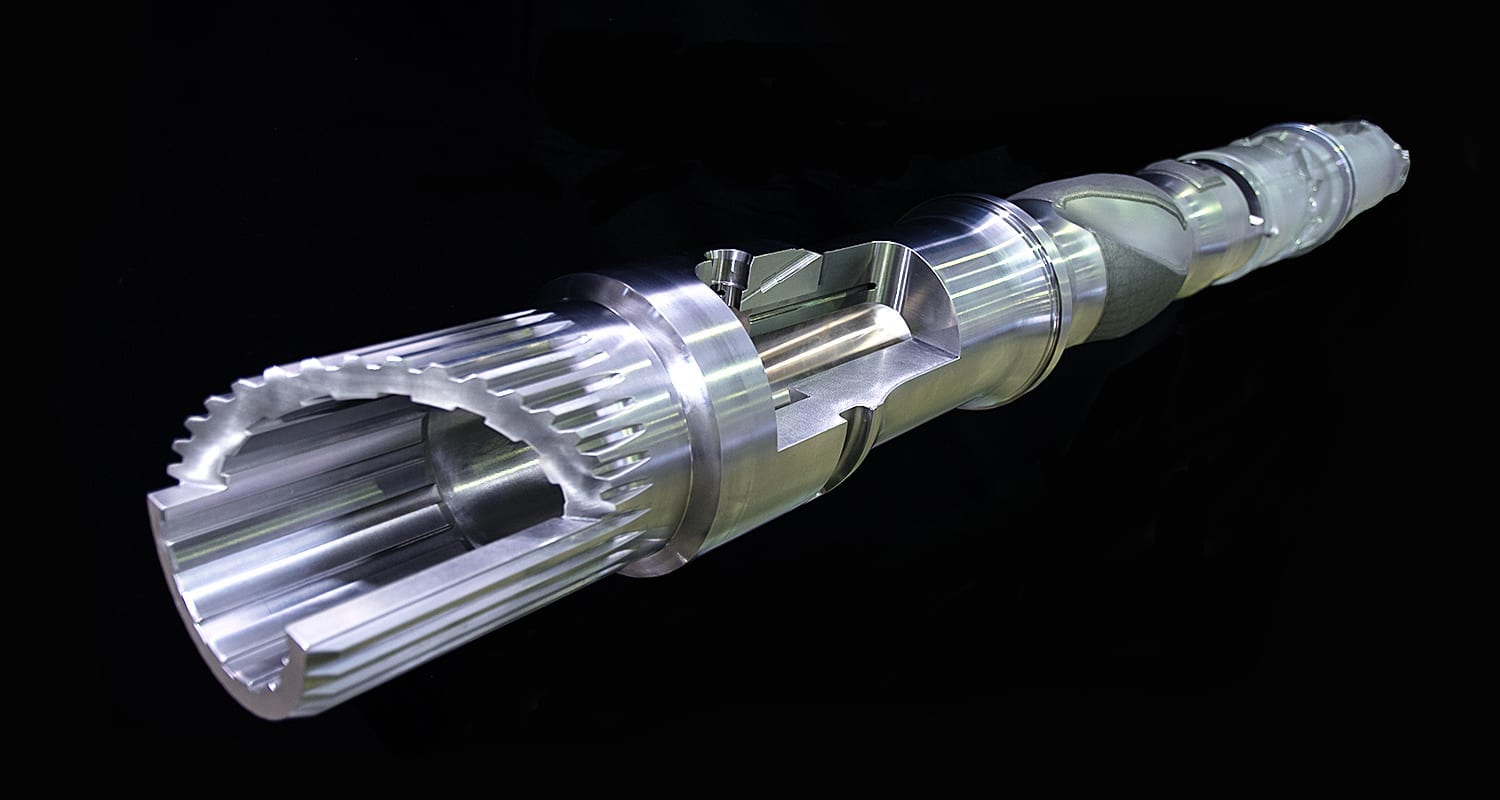

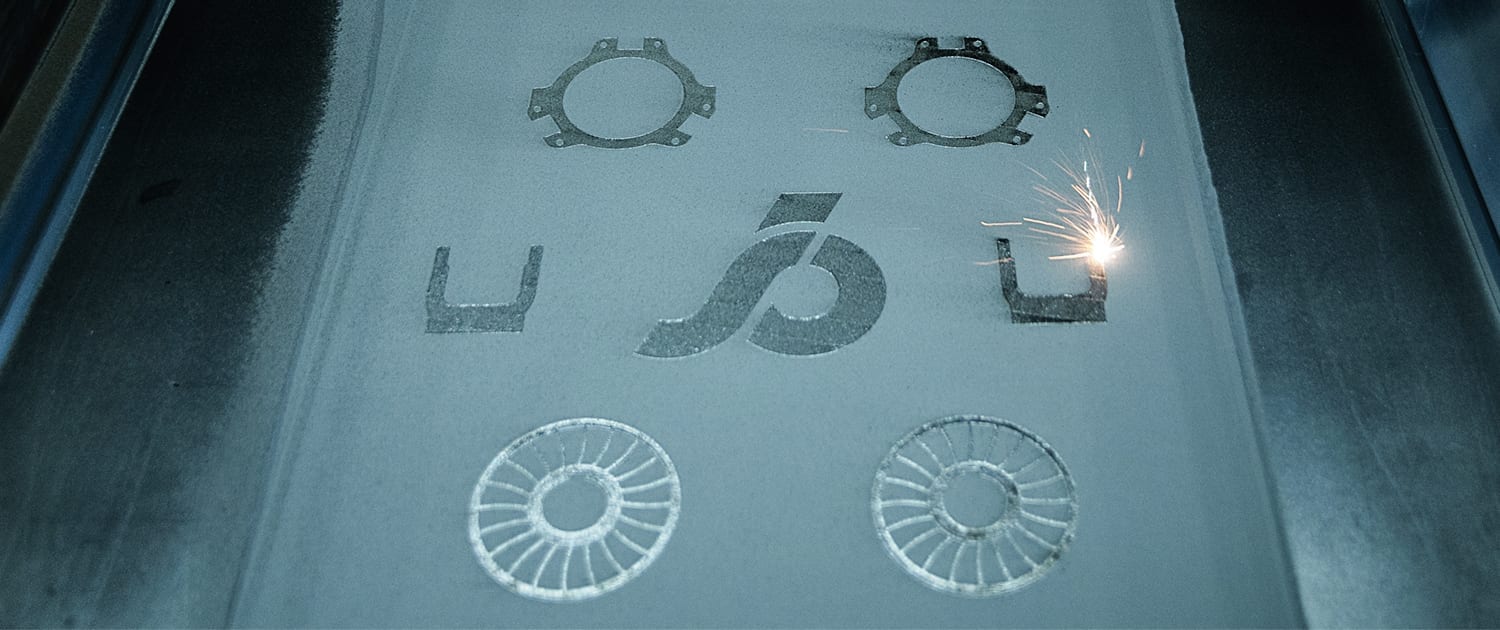

At SBOT, we have been machining parts in the 1/4 inch range up to 33 ft (in special cases up to 52 ft) long from high-strength, high-alloy steel as standard – for over 100 years.

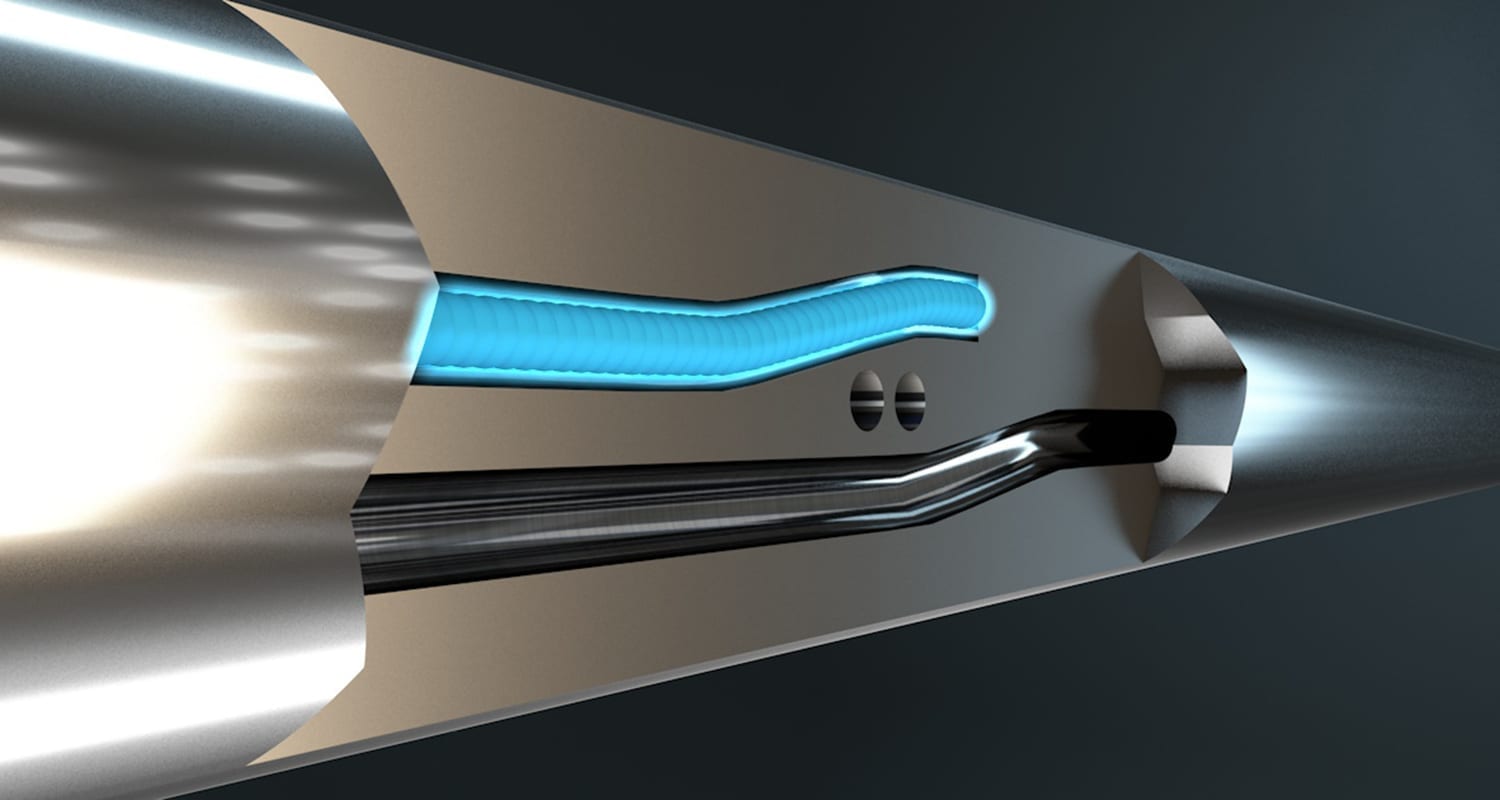

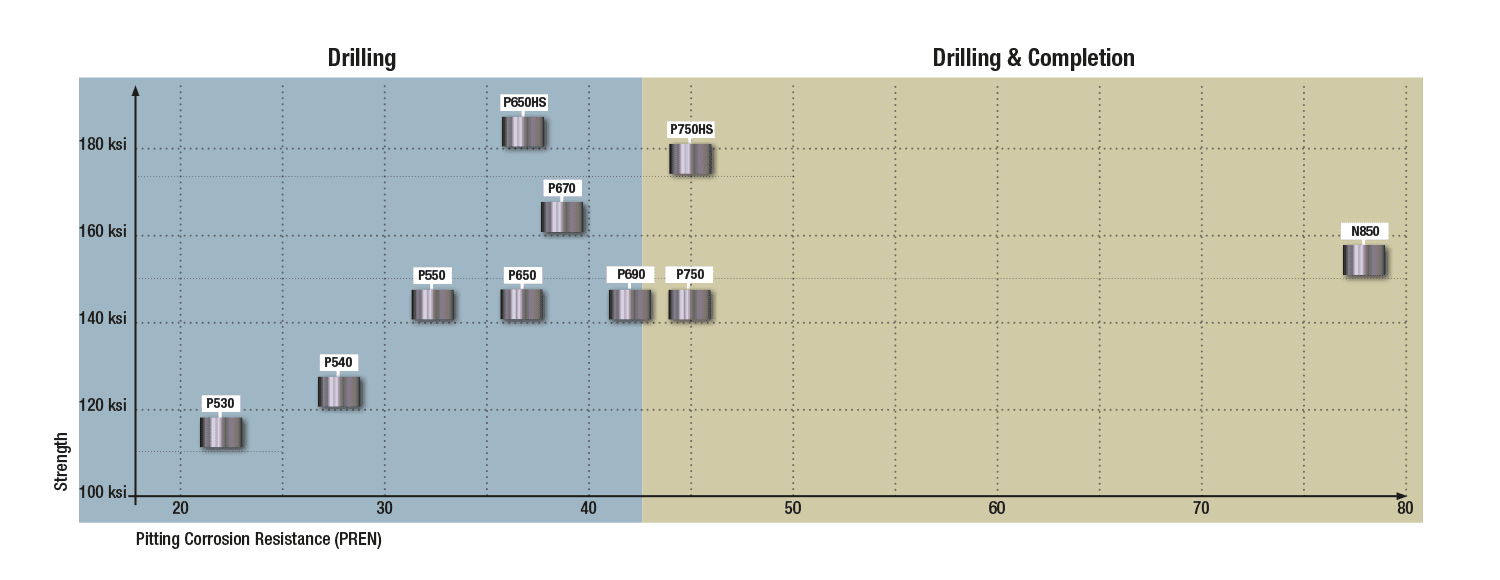

As the global market leader in the oil and gas industry, we offer both self-developed non-mag brands and finished MWD parts.