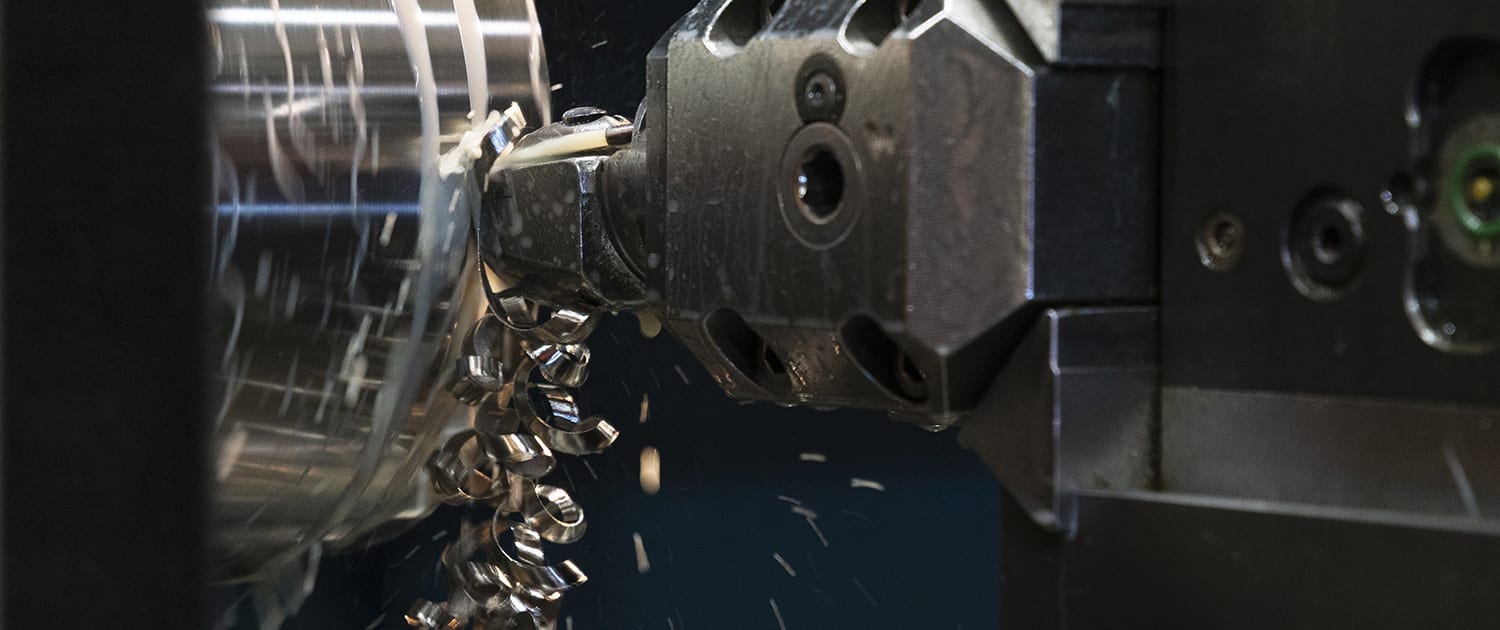

Turning/milling machining in one clamping up to 35 ft workpiece length.

On our encapsulated 5-axis Millturn machines, highly complex workpieces can be precisely and completely machined. The use of vibration-damped drilling tools also makes machining bores up to maximum 14 x D (bore diameter) possible.

Benefits

Special Machining Applications:

- HSC – milling

- Simultaneous 5-axis milling

- Gear hobbing

- Rotary milling

- Hub trunnion milling

- Cam milling

- In-process measurement

- Peeling

- Keyway slotting

- Deep groove cutting

Materials

- Ferritic & austenitic steels

- Duplex & superduplex Steels

- Nickel & titanium alloys

- Bronze & copper alloys

Structure Of Complete Rotary Milling Centres

The design of a complete machining is a combination of a lathe and a machining centre.

The machine bed, the main drive, the workpiece clamp and support, for example by steady rests or tailstock, resemble a lathe. The tool carrier and the tool changing system are designed in a similar way to a machining centre.

Particular attention must be paid to the tool system in the case of complete machining centres. The tool interface must fulfil both the tasks of the static turning tools and those of the rotating milling and drilling tools.

Worth knowing: Deep drilling lexicon, Botek, TBT

Key Technical Data

| Manufacturing Options | min. | max. |

|---|---|---|

| Length of workpiece | 31,5 in | 421,3 in |

| Diameter of workpiece in steady rest | 3,1 in | 23,6 in |

| Diameter of workpiece Ø over machine bed | 47,2 in | |

| Component Weight | 6,3 t |