With our 5 blasting machines we offer our customers the possibility of improving the properties of their workpieces by means of shot peening.

By introducing residual compressive stresses into the edge zone, the resistance to stress corrosion cracking and vibration corrosion cracking of high-alloy steels is decisively improved and the fatigue strength is increased.

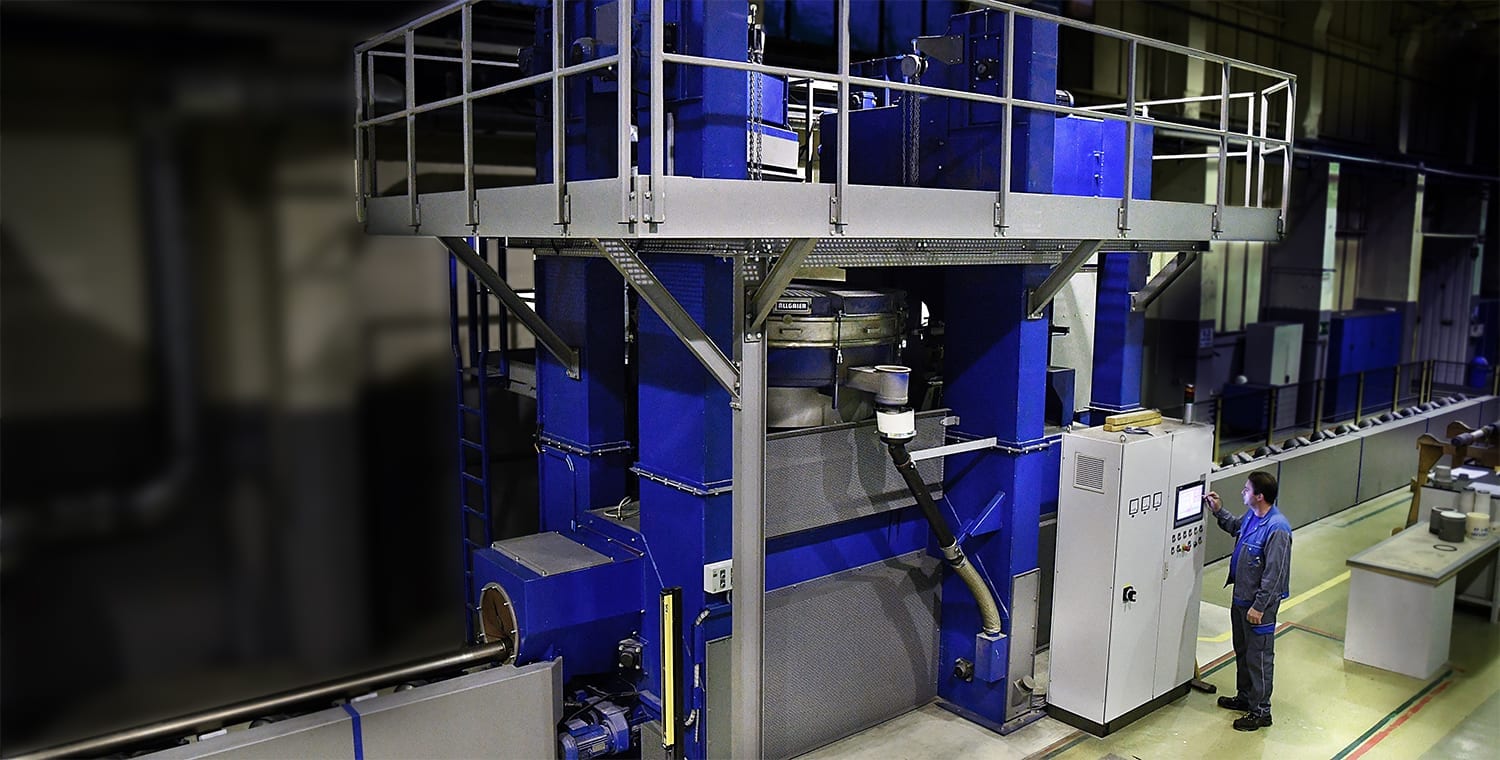

Figure 2/ Shot peening

Our three ceramic blasting systems and two high-energy blasting systems are designed as compressed air and/or wheel-blast systems. In order also to be able to treat bores upwards of 1,26 in diameter, the machines are equipped with an NC-controlled beam lance as well.

We specialise in rod- and tube-shaped workpieces from 2,3 to 40 ft in length with an outside diameter from 1,2 to 20 in.

Benefits

Special Applications Of Shot Peening

- Blasting of bores

- Round workpieces up to 40 ft long

- Innside and outside diameter

- Thread

Materials

- high-strength steels

- high-alloy metals

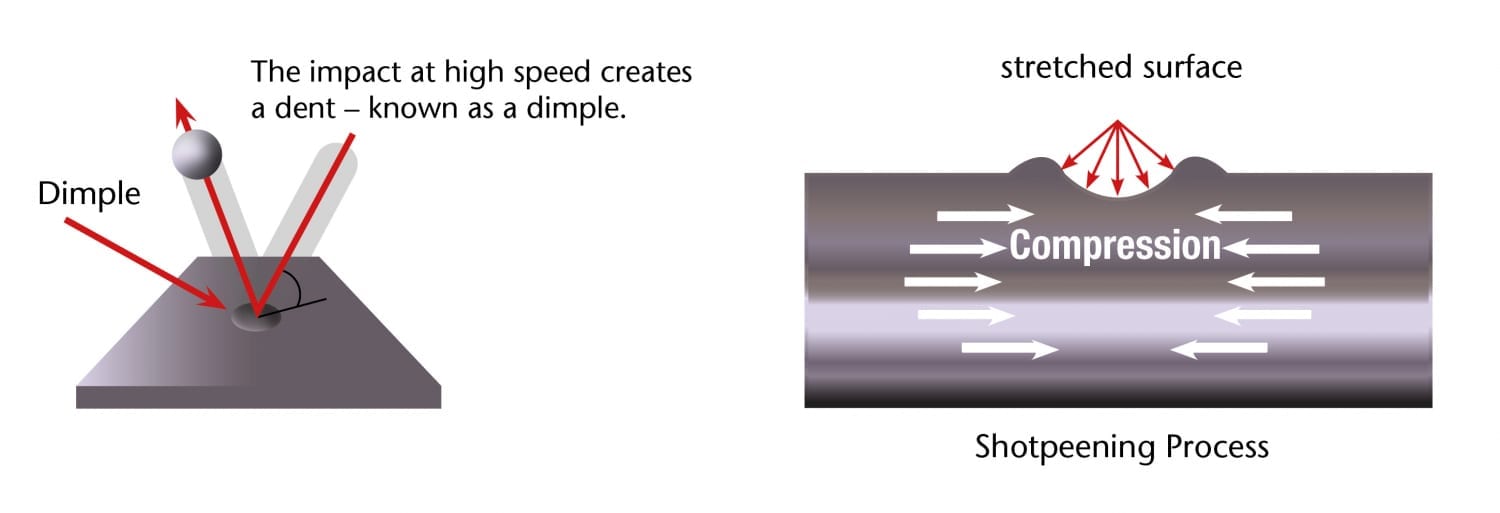

Shot Peening – The Process

The purpose of this process is to eliminate the tensile stresses present in some materials and thus improve their fatigue strength. Stress and vibration crack corrosion can also be greatly reduced as a result of this process.

The residual compressive stresses introduced into the workpiece are achieved by using a blast wheel, compressed air or an injector in the blasting system to hurl the abrasive (ceramic grains, stainless steel wire grain) at high speed against the surface of the workpiece to be treated.

The residual compressive stresses applied are responsible for the improved properties of the material and can be precisely determined, either indirectly by the Almen intensity or directly by a destructive test.

If compressive residual stresses are now introduced into the material by means of shot peening, they must first be overcome by tensile forces before a crack can occur at the edges of the material.

In cooperation with MFN, we train our employees in this technology and continuously improve their skills. In this way we ensure that our high quality standards are maintained.